Moulding

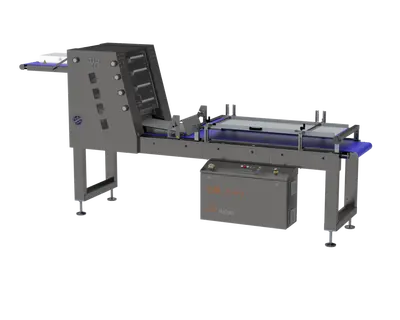

BM 2-40

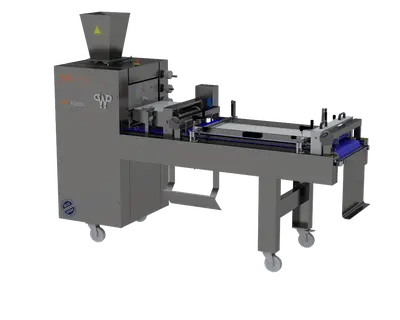

BM 3-40

BM 4-80 BT

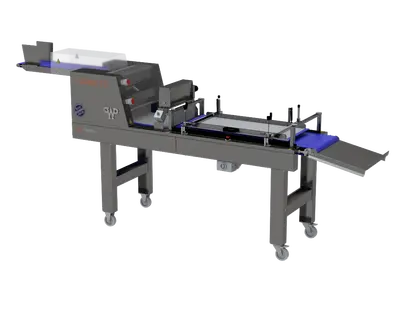

BM 51 B/L

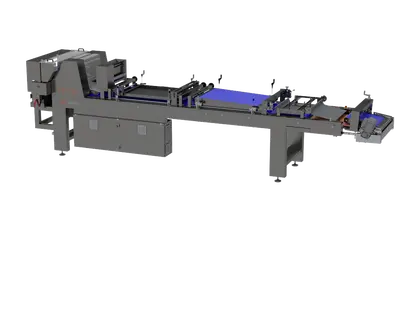

COMBI 4

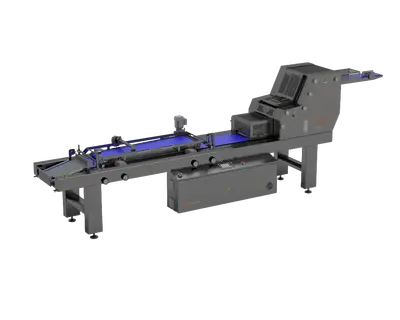

COMBI E1

COMBI E2

COMBI U

FF 700

Only part of our range is shown, for more information contact us at prodaja@omrcen.hr

Moulding from the Dutch manufacturer WERNER & PFLEIDERER HATON.

The BM 2-40 is an industrial long moulder for pan and hearth bread, suitable for wheat dough and mixed wheat/rye dough. The curling belt and sheeting belt are separated for optimized roller speed and sheeting time. Additionally, the opening between the sheeting rollers as well as pressure board and side guides can be easily adjusted for dough friendly handling of different dough types to get the best end result.

The BM 3-40 is a high performance industrial long moulder for pan and hearth bread, suitable for wheat dough and mixed wheat/rye dough. The curling belt and sheeting belt are separated for optimized roller speed and sheeting time. Additionally, the opening between the sheeting rollers as well as pressure board and side guides can be easily adjusted for dough friendly handling of different dough types to get the best end result. The optional Twister can easily be lifted when its use is not necessary.

The BM 4-80 BT is a high performance industrial long moulder suitable for wheat and wheat/rye dough that can process up to 4,200 pcs per hour. Sheeting of round dough pieces as well as oblong pre-moulded dough pieces is possible on this high-capacity moulder. The four pairs of rollers each have their own drive, allowing perfect progressive sheeting of the dough pieces. The settings on the BM 4-80 BT are automated and recipe driven to ensure dough friendly handling of different dough types to get the best end result.

The BM 51 B is a long moulder suitable for wheat and wheat/rye dough. The dough pieces are sheeted by the first pair of sheeting rollers. Then the dough pieces are folded by folding blades. These blades determine the length, model and structure of the dough piece and can be used depending on type of dough. With the addition of the second pressure board (=L) the dough pieces have a longer dwell time, adding more windings and gentle pressure to the dough pieces for a good structure of the dough.

The Combi 4 is a universal industrial long moulder for tin and hearth bread. This long moulder can process wheat dough and mixed wheat/ rye dough. By tipping the dough pieces over, the water in the back end of the flattened dough piece will be transferred to the front side. The water will remain inside the dough piece when it has been rolled up under the curling chain, resulting in improved freshness and shelf life of the final product.

The Combi E1 is a long moulder suitable for the production of various breads made of wheat, rye and multigrain dough. The Combi E1 arranges a precise centring of the dough pieces before sheeting and long moulding. It is a compact long moulder able to dough friendly handle a wide range of dough types. The highly accurate sheeting ensures a high level of consistency of the final products.

The Combi E2 is a long moulder suitable for the production of various breads made of wheat, rye and multigrain dough. The even sheeting of the pre-proofed dough pieces is done by two sets of sheeter rollers. Variable speed settings on the sheeter rollers ensure progressive sheeting of the dough pieces. Both the pressure board and side guides of the Combi E2 can be adjusted for optimal moulding results. The highly accurate sheeting ensures a high level of consistency of the final products.

The Combi U is a long moulder suitable for the production of various breads made of wheat, rye as well as very wet dough. This long moulder is capable of handling round, long and flat dough pieces, whereas non-sheeted dough can be processed via a bypass to be folded only. The roller pairs can be opened, serving as conveying rollers for the production of round loaves and rye dough. The curling net of the Combi U is adjustable, regulating the pressure on the dough piece as to reach the best end result.

The FF 700 is an industrial moulder especially designed for processing baguettes and other Mediterranean types of bread. Through the servo driven intelligent centring conveyor, the dough pieces are fed into the moulder where the dough pieces are moulded by a pressure board and top moulding belt which are both adjustable in height. At the end of the FF 700, the dough pieces are transferred to a panning conveyor for further processing.